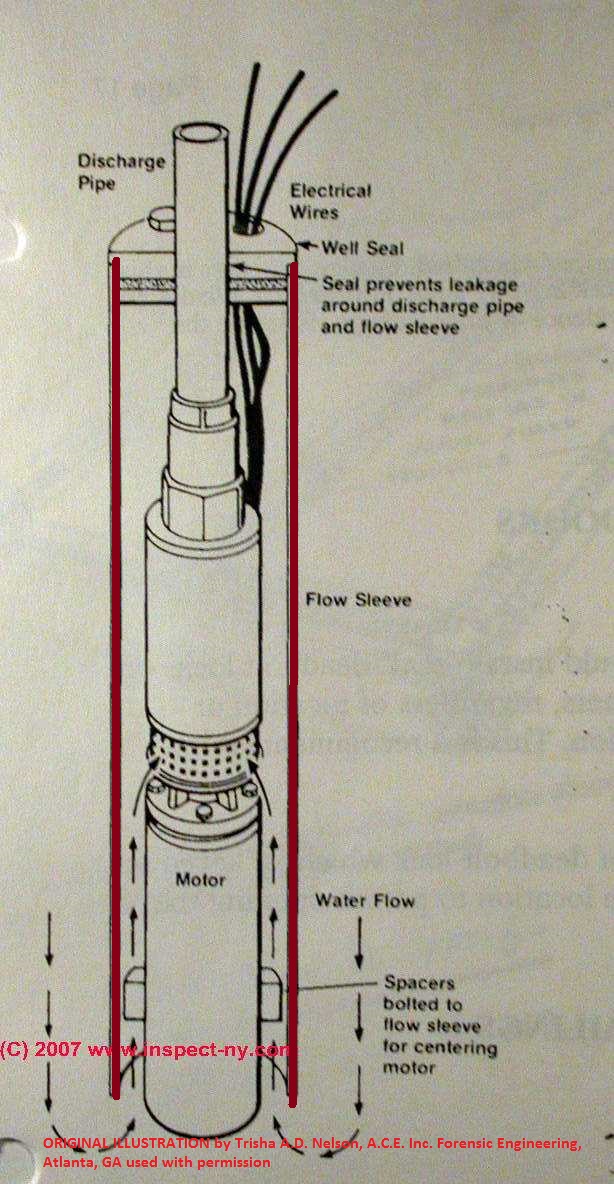

Submersible pumps are devices that are used to push fluids

and are mainly useful in transporting water. The main characteristics of these

pumps are that they are fully submerged in the liquid that needs to be pumped

out. The pumps are all sealed in order to prevent fluid from entering the motor

and cause failure. These pumps along with industrial

pumps are known as utility pumps and are highly prevalent in the market

today. These pumps are better than jet pumps because they are more powerful and

effective.

Submersible pumps are used in various applications including domestic, agricultural and industrial areas. They are also used to dig oil and water wells. They also provide an easy access to underground water. Single stage pumps are used for drainage, sewage pumping, general industrial pumping and slurry pumping. On the other hand, multiple stage submersible pumps are used for water abstraction, water wells and in oil wells. The main feature of these pumps is that they are comparatively silent and can be installed with ease.

Submersible pumps are used in various applications including domestic, agricultural and industrial areas. They are also used to dig oil and water wells. They also provide an easy access to underground water. Single stage pumps are used for drainage, sewage pumping, general industrial pumping and slurry pumping. On the other hand, multiple stage submersible pumps are used for water abstraction, water wells and in oil wells. The main feature of these pumps is that they are comparatively silent and can be installed with ease.

There

are a few specifications that you must keep in mind at the time of selecting

one of the best pumps for your needs. They include:

- High degree of expulsion flow

- High degree of discharge force

- Size of the discharge

- Power of the motor

- Durability

- Resistance to wear and tear

- Long lasting features

Buying

one of the best submersible pumps or

industrial pumps require a lot of

research because these machines are complex in nature. You must always buy

pumps for your industrial units from a company that holds good repute in the

market of pumps. You can find some of these professional companies on the

Internet because there are ample websites that help buyers select the best

pumps for their industrial units.